Carbon Steel 1020

At All Metals & Forge Group, we take pride in providing our customers with a wide range of products and services. Below you’ll find a menu with links to detailed reports on some of our most popular alloys. If you would like us to send you our complete list of reports for the over 300 alloys we offer, use the form below to let us know where to send your alloy reports.

As always, if you have any questions please contact us in the U.S. at 1 (973) 276-5000 or toll-free at 1 (800) 600-9290. In Canada at 1 (416) 363-2244. Fax us at 1 (973) 276-5050 or email us at sales@steelforge.com. We look forward to hearing from you.

CARBON STEEL 1020

GENERAL CHARACTERISTICS OF LOW-CARBON STEEL 1020

C1020 is a general-purpose carbon steel that may be hardened by carburizing or by other surface treatments.

APPLICATIONS

This grade of steel is used for forged motor shafts, hydraulic shafts, and pump shafts, as well as machinery parts.

FORGING

C1020 is forged from around 2300ºF (1260ºC) down to a temperature in the region of 1650ºF (900ºC.) The actual forging and finishing temperatures will depend on several factors, including overall reduction during forging and the complexity of the part being forged.

Experience alone will determine near-exact values for these two parameters.

Parts are air-cooled after forging.

HEAT TREATMENT

A significant amount of this grade of steel is used in the as-forged condition since it shows good machinability in this condition. Little is to be gained, at this carbon level, by a quenching treatment. At this carbon level, annealing after forging may not be necessary, and depending upon the hardness after forging and the complexity of the part being forged, machining may be carried out on the as-forged parts. If parts are of complex shape and hence there are structural variations throughout the part, then normalizing is in order.

NORMALIZING

Normalizing is seldom carried out on carbon contents at this level, but may be used before surface hardening. The normalizing temperature range for this grade is typically 1650-1700ºF (900-930ºC.) followed by air cooling. When forgings are normalized before, say, carburizing, the upper range of the normalizing temperature is used. When normalizing is the final treatment, the lower temperature range is used.

HARDENING

This grade of steel is not normally subjected to hardening and tempering treatments as the hardness obtained from such treatments would not warrant their being performed. Carburizing might be carried out at 1620-1690ºF (880-920ºC,) and carbonitriding at 1470-1600ºF (800-875ºC.)

Hardening of the carburized case would be performed at 1430-1500ºF (780-820ºC) followed by a water quench and a tempering treatment at 300-400ºF (150-200ºC) to improve case toughness with a minimum effect on its hardness. Case hardness values of Rc 60 may be obtained on carburized C1020.

MACHINABILITY

For parts with a diameter less than 2” (50mm) this grade has been found on occasion to show best machinability when normalized. Parts over 2” (50mm) diameter might be machined following forging or rolling.

WELDABILITY

This grade of steel may be welded by all normal methods: low-carbon electrodes are recommended.

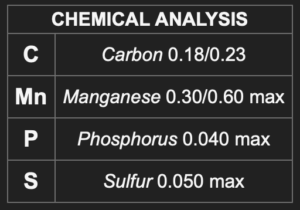

Let us know where to send your complete Alloy Report including chemical analysis, machinability, weldability, heat treatment, and more.

Fast Quotes And Delivery

Save time and money on your next project.

In the U.S. 1 (973) 276-5000 / 1 (800) 600-9290.

In Canada 1 (416) 363-2244.

Email us at sales@steelforge.com.