In today’s competitive manufacturing landscape, time is often just as valuable as material. Machine shop owners and manufacturing buyers are constantly under pressure to deliver high-quality parts while keeping costs manageable. The most effective way to achieve this balance is through near-net shape open die forging, a process that not only improves quality but also significantly reduces production lead time.

Why Lead Time Matters in Gear Manufacturing

Whether supplying a single replacement gear or coordinating a larger production run, long lead times can disrupt schedules, increase costs, and strain customer relationships. Delays often come from excessive machining time, material availability, or additional finishing processes.

Manufacturers that adopt fast gear manufacturing techniques, like starting with a near-net shape forging, gain an edge by addressing these bottlenecks early in the process.

The Advantages of Near-Net Forging

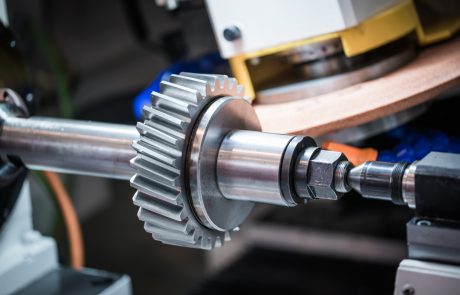

A primary reason open die forging streamlines production is its ability to create near-net-shapes. Instead of starting with an oversized geometry that require extensive machining, near-net forgings are produced close to final dimensions. For gears, this means less material removal, fewer machining hours, and decreased tool wear.

- Less machining = faster turnaround times

- Reduced scrap = lower material costs

- Closer tolerances = easier path to finished parts

By moving directly from forge to machining with minimal adjustments, machine shops save valuable time without sacrificing quality.

Quality Built into the Process

Speed is important, but not at the expense of durability. Open die forging aligns the grain flow of the metal with the part’s geometry, producing stronger and more fatigue-resistant gears compared to those made from cast or fabricated alternatives. This natural strength means fewer reworks, less downtime, and longer service life – all factors that help reduce total project timelines.

Ultrasonic Testing for Reliability

Another way forging reduces lead time is by integrating ultrasonic testing early in the process. This nondestructive inspection method detects internal flaws, such as inclusions, cracks, or voids, before machining even begins. Identifying and addressing potential issues upfront eliminates wasted hours on defective parts and assures that the gears moving through production meet required standards.

Real-World Cost Savings

For many machine shops, the combination of near-net forging and quality assurance translates into measurable benefits:

- Shorter production cycles: From raw material to finished gear in fewer steps. Lower machining costs: Reduced tool time and tool wear.

- Improved reliability: Less downtime from premature gear failures.

- Better planning: Confidence in delivery schedules and inventory management.

Instead of waiting months for mill runs or dealing with unpredictable supply chains, open die forging provides flexibility and adaptability, especially valuable when handling custom orders or replacement parts under tight deadlines.

Efficiency Without Compromise

For companies aiming to stay competitive, reducing gear production lead time is no longer optional; it’s essential. Open die forging offers a proven path to achieve fast gear manufacturing while maintaining quality and cost-effectiveness. By taking advantage of near-net forging and built-in quality measures like ultrasonic testing, manufacturers can streamline workflows, cut unnecessary costs, and meet demanding deadlines.

What other methods do you use to operate more efficiently in your shop? Have you considered how open die forging could shorten your next project timeline?

Contact All Metals & Forge Group today at sales@steelforge.com to learn how forged gears and parts can help your business improve productivity, reduce lead times, and stay ahead of the competition.