by Royce Lowe

Gears are manufactured in many shapes, from a number of alloys. Each gear has its own method of transmitting motion and force. The most common gear shapes and their applications are as follows:

A spur gear has straight teeth, mounted on parallel shafts, and is used to transmit motion between these shafts. Typical applications are in clocks, washing machines, and conveyor systems.

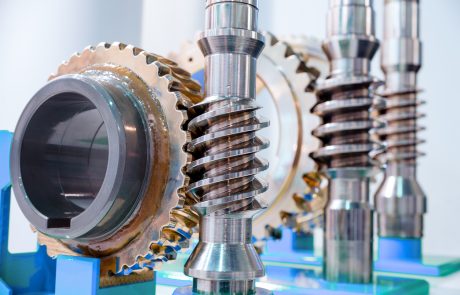

Helical gears have teeth cut at an angle to the gear axis. They have a smoother and quieter operation than spur gears and can handle more load. They find use in automotive transmissions, elevators, and compressors.

Bevel gears have a conical shape, with teeth cut on the cone surface to transmit motion between intersecting shafts, normally at 90 degrees. They may be used in hand drills, or in automotive differential drives.

A worm gear is a screw-like (worm) gear that meshes with a spur gear (worm wheel.) It has self-locking capability, and is used on elevators, tuning instruments and conveyor systems.

Rack and Pinion gears are composed of a linear gear (rack) that meshes with a circular gear (pinion). They effectively convert rotational motion into linear motion, and are used in steering systems, CNC machines, and railways.

Hypoid gears are like bevel gears but have offset shafts. They allow smooth and quiet operation with high torque transmission. A major use is in automotive differentials.

Spiral Bevel Gears are bevel gears with curved teeth and are quieter and stronger than straight bevel gears. They find use in helicopter transmissions and industrial machinery.

Herringbone Gears are effectively two helical gears joined together with opposite helix angles. This arrangement cancels out axial thrust and allows smooth operation. These gears are used in heavy machinery and turbines.

The alloys used for the manufacture of gears will be largely determined by such factors as strength, toughness, and wear resistance required. In some cases, the strength-to-weight ratio is important, as with aluminum alloys, where corrosion resistance may also be primordial in the end use. Aluminum alloys find applications in aerospace, robotics, and portable devices.

Most gears are made from ferrous materials, such as cast iron for example, where cost might be a factor, and the mechanical properties of the cast material are sufficient for the application. Cast iron is used in agricultural machinery and compressors. Medium and high carbon steels are used where strength and toughness may be developed by heat treatment, and where the corrosive environment is not hazardous. Applications include aerospace parts and mining equipment.

Where increased strength, toughness and wear resistance are required, alloy steels are the order of the day. These are medium carbon steels with nickel, chromium and molybdenum additions to improve hardenability and strength, toughness and corrosion resistance. In certain cases, if the steel’s chemistry allows it, heat treatments such as carburizing or nitriding may be used to increase surface hardness while retaining a tough core. If corrosive conditions call for increased protection, then martensitic stainless steel might be used – for both corrosion resistance and increased mechanical properties.

Copper-based alloys, such as brass, phosphor-bronze and aluminum-bronze are used as corrosion-resistant, both low- and high-friction gears. Aluminum bronze is used in marine and corrosive environments.

AMFG produces gear blanks from alloy, carbon, stainless, and tool steel, nickel alloys, titanium, and aluminum. Customers finish machine the teeth to their specific requirements.