the United States leads in fracking

by Royce Lowe

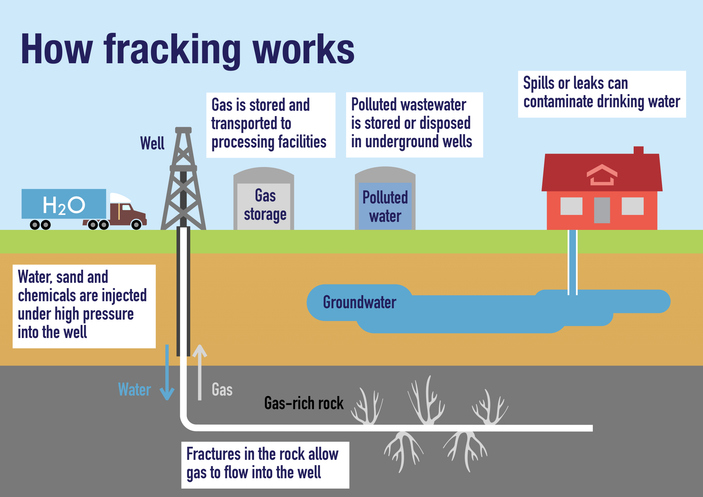

The United States has always been one of the world leaders in the oil and natural gas business. Still, with the intensity of fracking a couple of decades ago, it became the world’s number one producer of crude oil and natural gas. Fracking, or hydraulic fracturing, is a technique for recovering gas and natural oil from shale rock. Put simply, it involves drilling into the earth and directing a high-pressure mixture of water, sand, and chemicals at a rock layer to release the natural gas inside. A few years ago, it was estimated that of a million or so oil and natural gas wells in the United States, around 70% were drilled and fracked.

Fracking requires strength

Another business that goes along with fracking is that of making, shaping, and treating the steel and other metals used to fabricate the drill collars, gears, valve bodies, and fracture pumps. There’s an awful lot of liquid involved in a fracking operation, with millions of gallons of water as the major constituent of the liquid feed, topped up by fracking chemicals and what are called proppants, a sand constituent that is there to keep open the fracking cracks formed from initial drilling. The oil and gas industry is one of the largest consumers of specialty pipe and tube products. These products are used in various applications, such as drilling, production, and oil and gas transportation.

The steel components used in the overall fracking infrastructure must be strong and resistant to the numerous thuds and shocks they’ll undergo during the drilling, extraction, and storage operations, as well as the abrasion from all the sand floating around. So, which grades of steel are recommended for use in the oil and gas industry?

Grades 4130, 4140, and 4340 are up to the task or performing well in this harsh environment. These are low alloy steels that may be heat treated to the required mechanical properties for their operating environment. They may be easily machined, particularly if heat treated to the spheroidized annealed condition. They are easily welded but should be treated with care. The three grades complement each other as applied to the oil and gas industry. This is the basic chemistry of the respective alloy steels:

Forged components are indispensable

We will note from the carbon contents that type 4140, for a given heat treatment procedure, will

produce a harder, stronger material than type 4130. Type 4340, a nickel-bearing steel, will produce the strongest material of the three. It will also hold its strength to around 600 degrees Fahrenheit. It is tough and will hold its toughness to sub-zero temperatures. The hardenability of type 4340 – the ability to be hardened to depth within the steel – is far greater than that of both 4140 and 4130.

Forged components are indispensable in the oil and gas industry thanks to their ability to withstand high pressure, low temperature, and corrosive environments. Key applications include forged flanges that provide secure and leak-proof connections in pipelines, valves, and pressure vessels. Pipelines for transportation would typically be made from 4130 grade, a somewhat less expensive material than 4340 but suitable for the application.

Forged components in the grades listed above will require heat treatment to specified strength and toughness levels. This requires detailed knowledge, garnered over years of experience, of the specific treatments required to obtain desired properties. The treatments may be annealing for optimum machinability or hardening and tempering to give the required strength and toughness levels.

In the event that the forged parts may exhibit non-uniform deformation throughout a part – because of a complicated shape – a normalizing treatment will be called for prior to undertaking hardening and tempering. It should be noted that the knowledge and experience of the people responsible for heat treatment are a very important part of this operation, as are those responsible for the forging, where forging temperatures and proper reductions come largely from past experience.

The three grades noted above, 4130, 4140 and 4340, will combine to form the necessary infrastructure for a fracking well. The cost of 4340 material will be significantly higher than that of the other two grades. These three steels, forged, heat treated, machined and welded, will all do their part in bringing oil and natural gas to industry and homes.

All Metals & Forge Group stocks raw material in these grades, so it can provide rough machined forgings in 8 to 10 weeks to fulfill your order. Contact one of our Forging Specialists at (973) 276-5000 or sales@steelforge.com.